Services

|

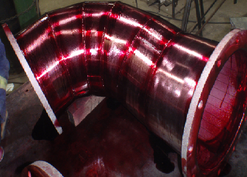

Magnetic Particle Inspection

Magnetic Particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part.

|

Visual Inspection

Visual testing (VT) is the oldest and most common nondestructive testing (NDT) techniques. It is typically the first step in the examination process to inspect a variety of product forms including castings, forgings, machined components and weld elements, according to the NDT Training & Test Center

|

Liquid Penetrant Inspection

Liquid Penetrant Inspection is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components

|

Ultrasonics

Ultrasonic methods of NDT use beams of mechanical waves (vibrations) of short wavelength and high-frequency, transmitted from a small probe and detected by the same or other probes.

|